Distribution Center Upgrades with Minimal Downtime

Recently, National Warehouse Logistics connected our team to West Marine. West Marine had reached out to National Warehouse Logistics looking for solutions to issues that they faced in updating their logistics warehouse system.

West Marine operated a major distribution center in South Carolina that used an antiquated software and conveyor system installed in 1997. West Marine had previously updated the system, but none of the updates were recorded or remembered.

The Challenge

West Marine’s controls were technologically out of date and posed risks to the business in potential costs and downtime. West Marine’s controls:

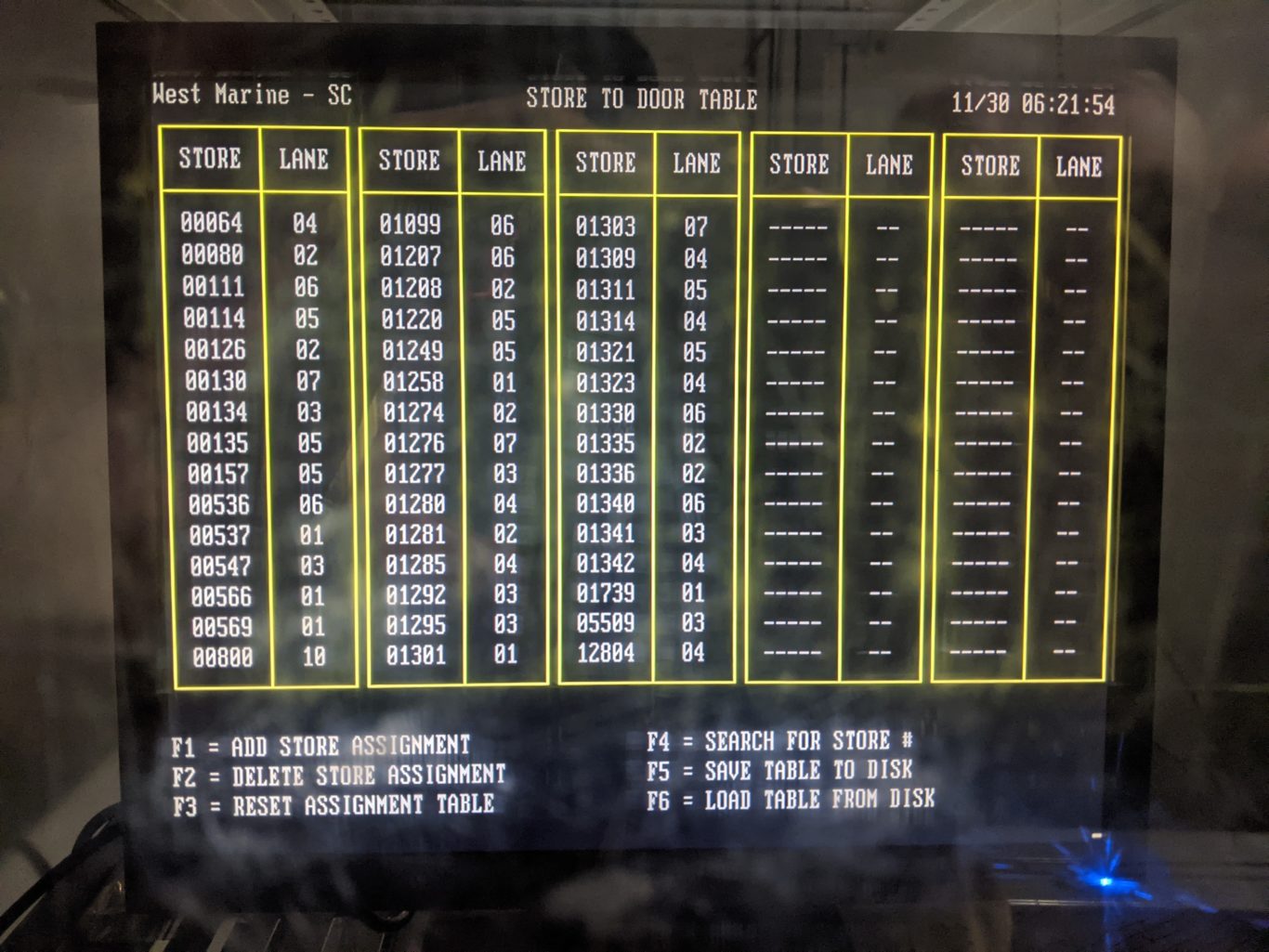

- Operated on Windows XP-compatible software, which was last updated in 2008, fourteen years prior.

- Used a text-based option screen that displayed primarily in basic black and white, making user interaction difficult.

- Solely relied on serial communications ports that have been mostly removed from consumer electronics and replaced by newer, faster communications.

- Was costly to repair. If the control system failed for any reason, West Marine discovered that it would take an investment upwards of $400,000, just to fix their existing hardware and software.

- Required 4 weeks of down time in order to install updates to the existing system, exasperating existing supply chain delays.

- Had little to no documentation of the software or warehouse processes, and West Marine staff generally weren’t sure how it worked. For all intents and purposes, the controls were a black box that operated without employee understanding.

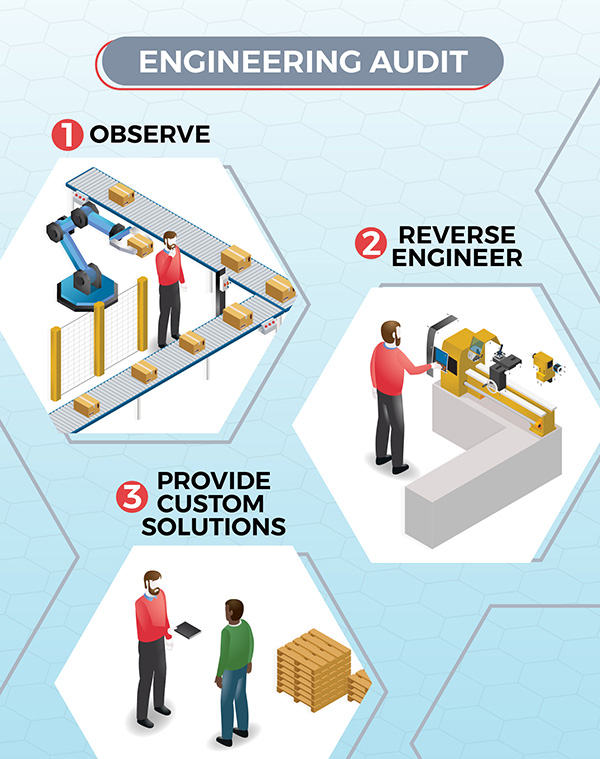

Reverse Engineering Old Systems

In the discovery process, it became clear that Hyperion would need to perform an engineering audit to better understand West Marine’s current warehouse operations. Through observing the existing logistics system, Hyperion reverse engineered processes to create a functional description of the system and provide a holistic solution.

The Solution

Hyperion’s team of experts implemented a slew of changes to increase productivity and reduce future costs and downtime for West Marine.

- To expedite future repairs, the Hyperion team replaced West Marine’s system with off-the-shelf input/output (I/O) modules and cards from Allen Bradley as well as a new main control panel to eliminate the need for a separate controls enclosure in the warehouse.

- Hyperion replaced the outdated serial communications system with ethernet connections.

- Updating the previous text-based interface, Hyperion also installed a user-friendly graphic-based display that included new information on machine status and performance.

In setting up the system, the Hyperion team also improved efficiency and safety through other changes.

- The new controls allowed the system to start up faster and added power saving capabilities.

- These controls also optimized sorter machine programming to minimize gaps in between products.

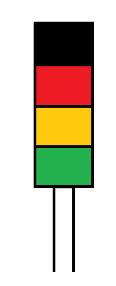

- New alarm systems above the main controls were also installed to alert employees using light and sound alarms of specific issues or important changes.

The Hyperion Difference

With pre-work done and a functional description of the system in hand, the Hyperion team installed West Marine’s new controls system in a fraction of the anticipated down time. Other than a weekend, West Marine’s main distribution center experienced no down time. Within four days of arrival, Hyperion had installed West Marine’s new controls along with updated software, and the final five days of Hyperion’s time at West Marine were to run the new, fully operational system in tandem with the old system running on stand-by.

In using standard controls components for West Marine, Hyperion ensured that any skilled vendor or employee could make changes in the future. West Marine now holds the keys to their own system along with the documentation necessary for future improvements. Any future improvements or maintenance would not require customizable parts, a large investment or significant down time.

More than that, this system vastly reduced business risks for West Marine. They can now perform maintenance without shutting down the entire distribution center for weeks at a time. West Marine has the freedom and redundancy to keep the warehouse running while one or two areas undergo maintenance or updates.

Support for Any Daunting Challenge

When customers such as National Warehouse or West Marine approach us with a challenge, our team is ready with the tools and curiosity to understand the challenge and present a whole-systems solution that meets our customer’s needs.

Have a complex problem you’re looking to solve? We’re here to help.