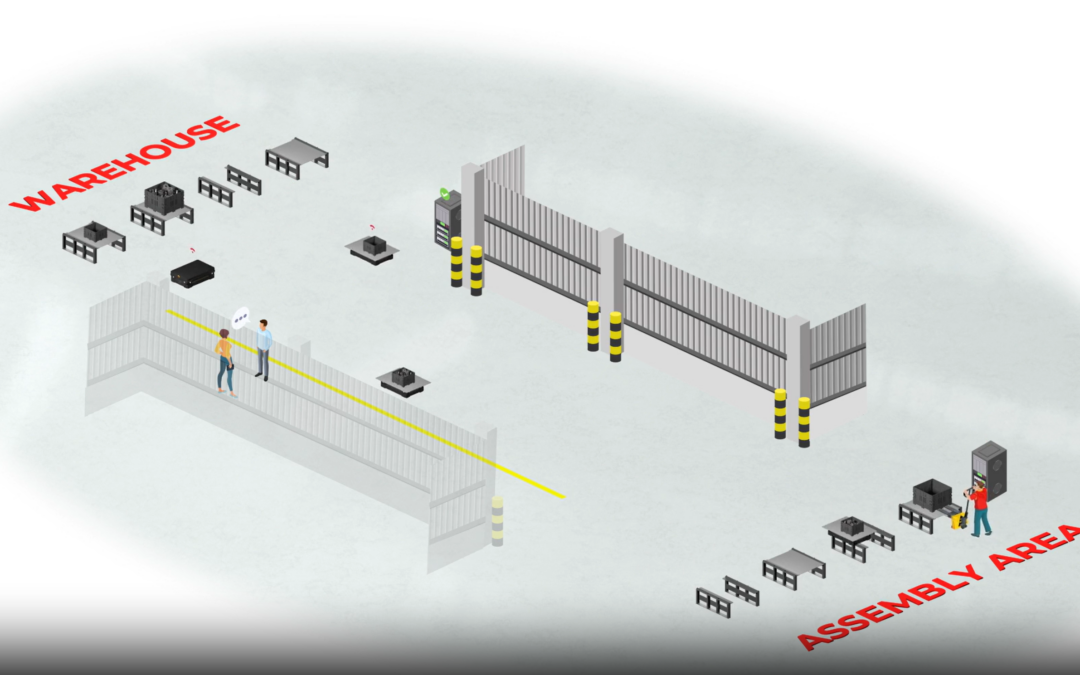

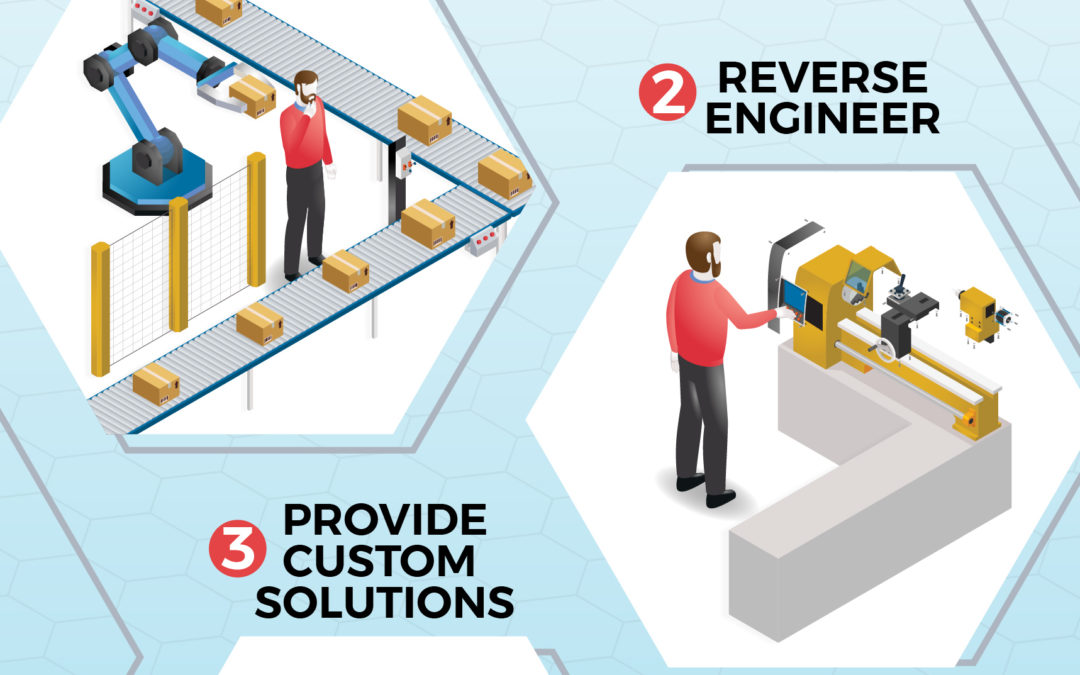

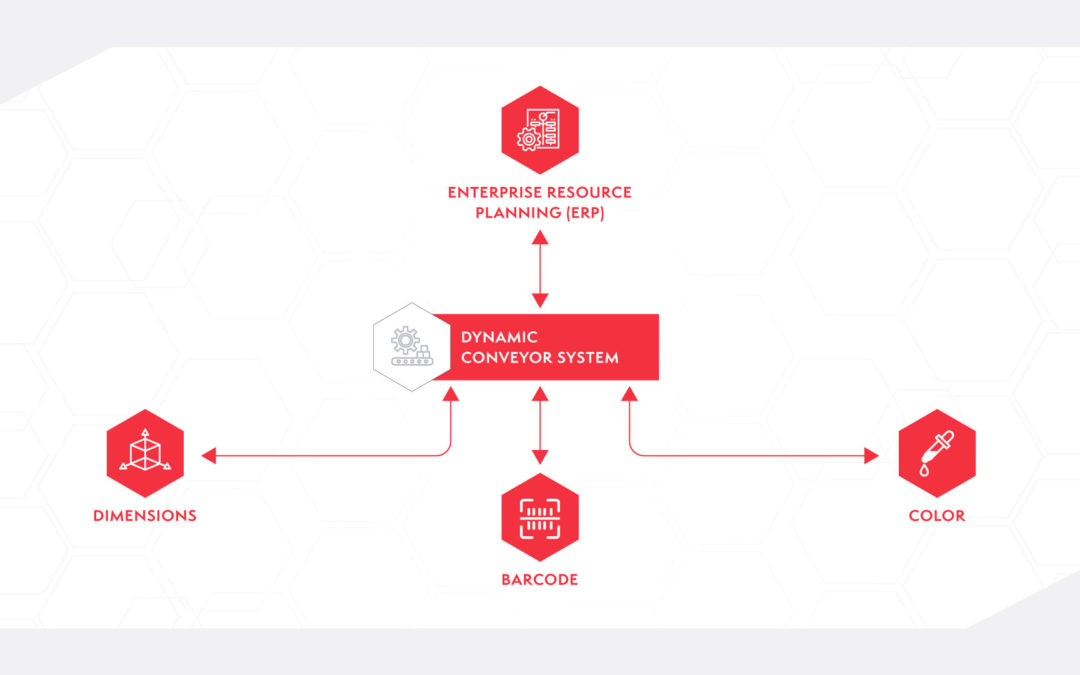

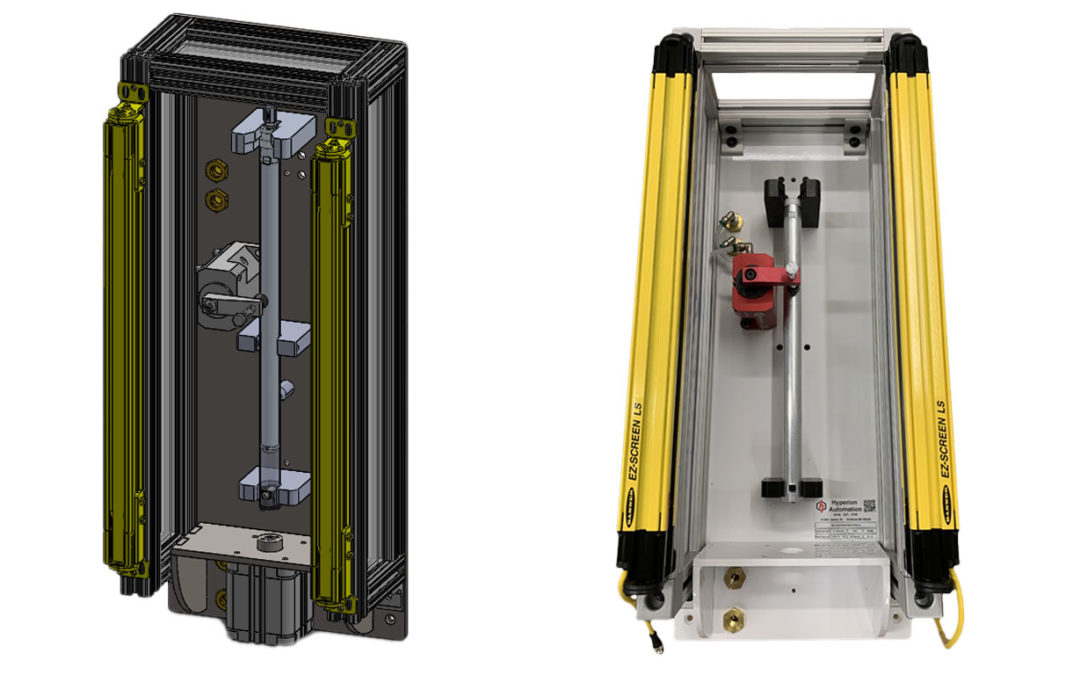

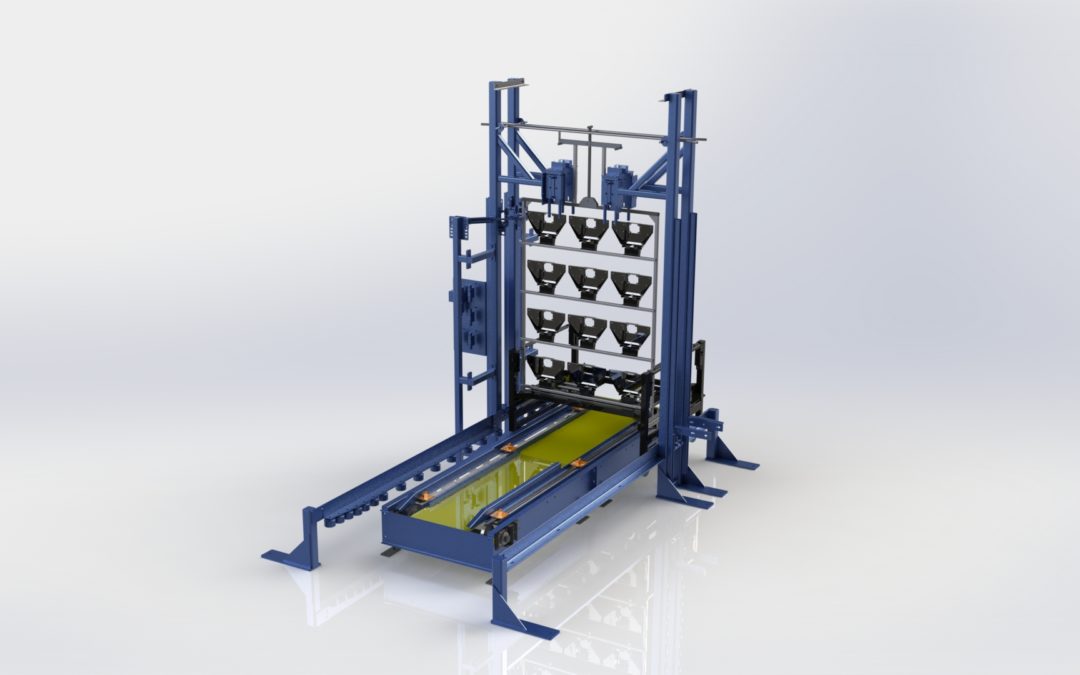

Recently, FPE Automation connected our team with a heat seal packaging manufacturer looking for a solution to increase safety and labor efficiency in their facility. They needed a strategic partner capable of integrating automation products into the facility’s...