An integration partner recently reached out to us for a solution to replace forklifts on their client’s manufacturing floor. The client had several constraints, including:

- Needing to use a smaller AMR (MiR 250) with a lower weight limit than the payload

- Needing to move full-size pallets safely

- Needing to move loads significantly heavier than the AMR’s payload rating.

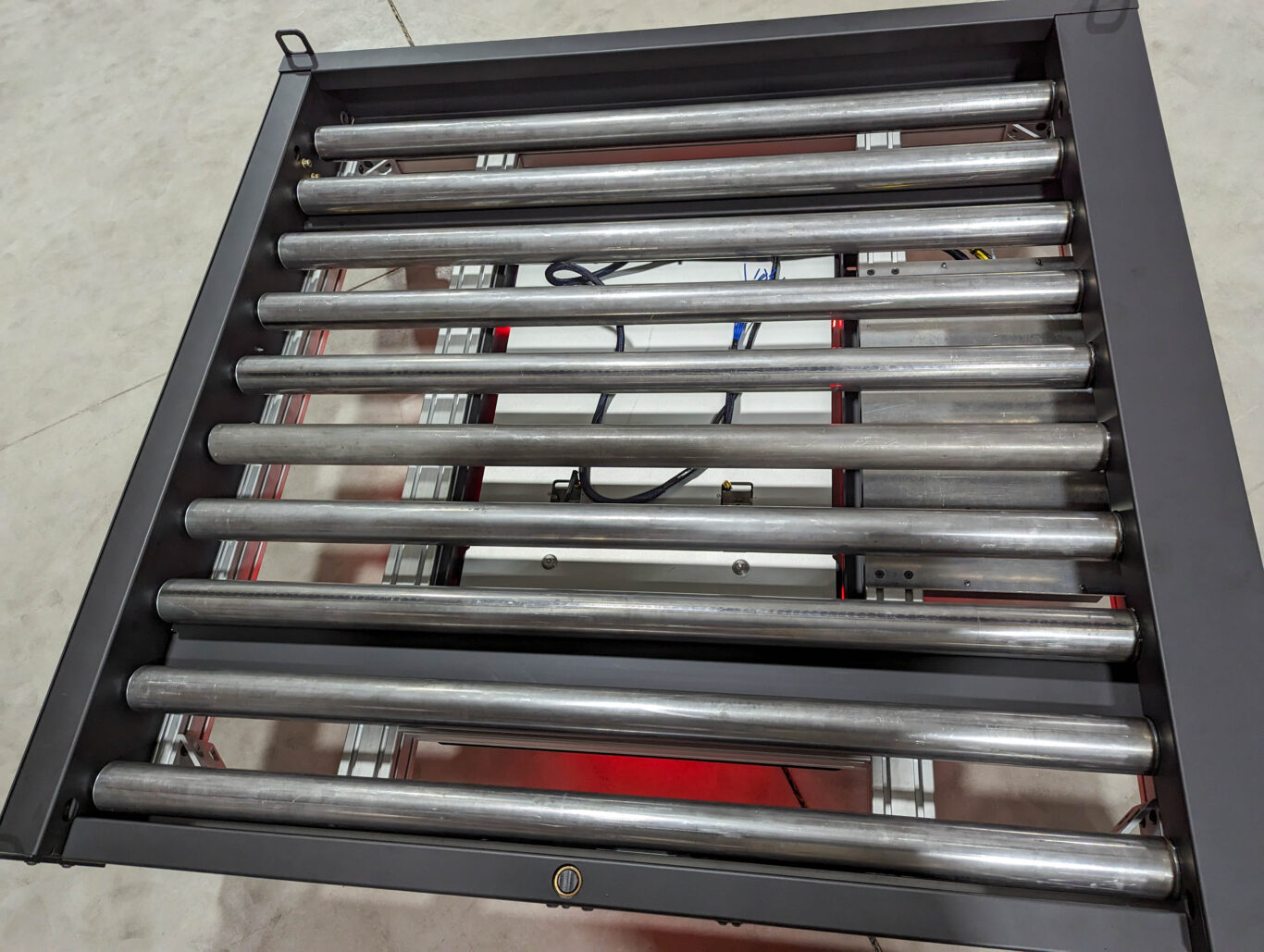

Our solution involved creating a carted conveyor model. The MiR 250 was paired with support posts and a conveyor top module, which the AMR pushes around the manufacturing floor. This allowed the customer to save money by repurposing the MiR 250 and adapt it to be useful for much heavier payloads.