Superior Automated Vehicle Solutions from a

MiR System Partner

We partner with top-tier companies like MiR to provide cutting-edge solutions to our clients. Our team’s extensive industry expertise and unwavering commitment to excellent service distinguish our partnership from the competition.

MiR-Powered Capabilities

Our experience with MiR equipment lets us integrate, program and optimize their products for specific applications, including:

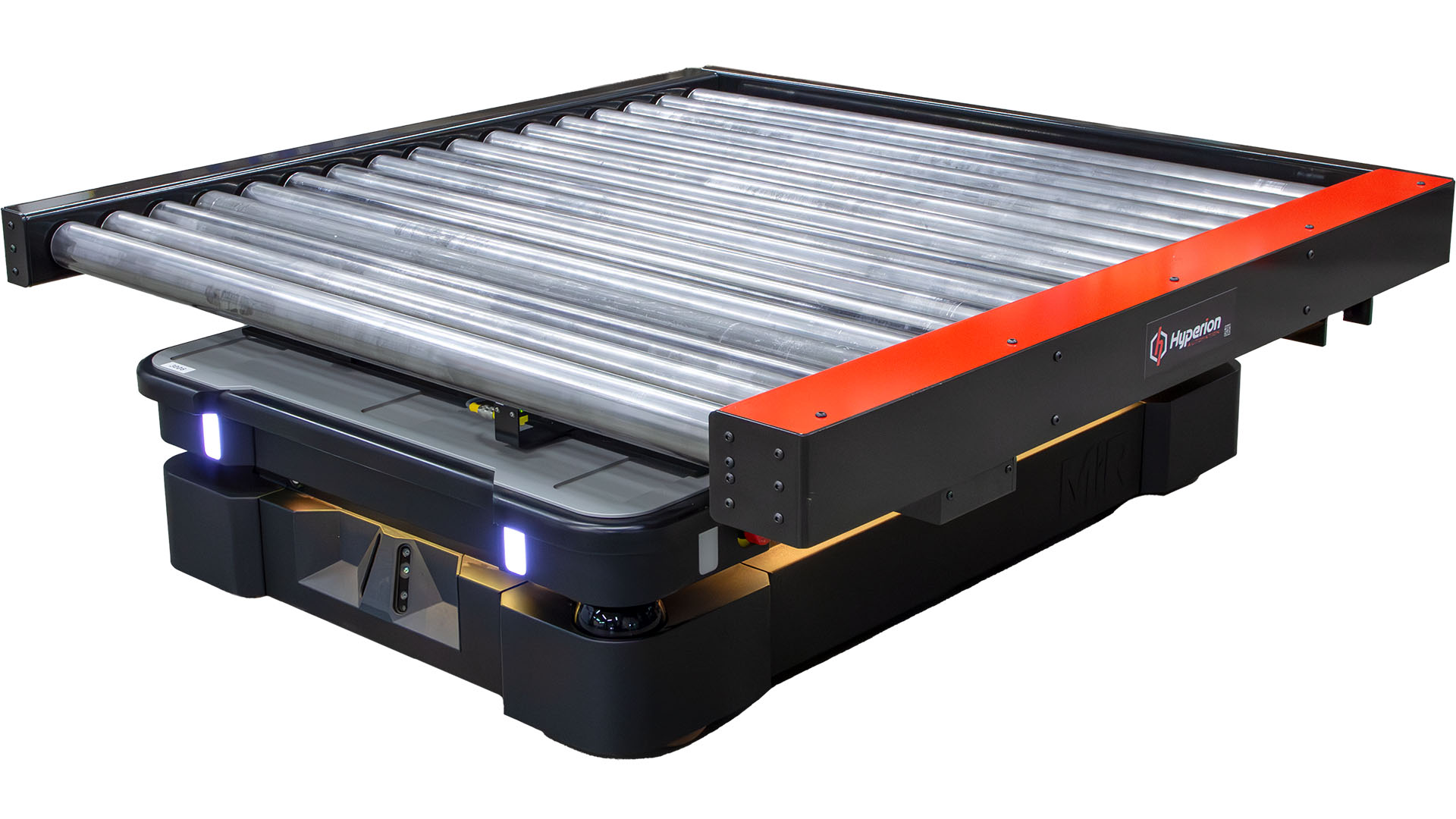

Conveyor Module Configurations

Front Loading

Easily load or unload parts from our custom-made front oriented top module.

Side Loading

Shrink your floor footprint with a conveyor that can pull up alongside each station without needing to reverse.

MULTI-ZONE

Use sensors and additional driving rollers to pick a kit of parts or load multiple parts for assembly.

ADJUSTABLE HEIGHT

Fully integrate your AMR to operate perfectly with your existing systems.

CASE STUDY: MIR AMR

Customizing Top Modules to Make the Most of Your Workforce

When an automotive parts supplier needed a unique robotics application that required customization of a MiR top module, local distributor Allied Automation connected them with the trusted team at Hyperion Automation.

Previously, the automotive supplier used carts and physical labor to pick parts for an assembly kit or to move parts around the floor, sometimes with a forklift.

Learn how we reduced labor costs, better utilized employee time, increased floor efficiency and improved employee safety through our custom top module solution utilizing the MiR500, the larger of MiR’s models.

CASE STUDY: MiR AMR

Carted Conveyor Solution Repurposes

AMR for Heavier Payload

An integration partner recently reached out to us for a solution to replace forklifts on their client’s manufacturing floor. The client had several constraints, including:

- Needing to use a smaller AMR (MiR 250) with a lower weight limit than the payload

- Needing to move full-size pallets safely

- Needing to move loads significantly heavier than the AMR’s payload rating.

Our solution involved creating a carted conveyor model. The MiR 250 was paired with support posts and a conveyor top module, which the AMR pushes around the manufacturing floor.

Hyperion’s solution allowed the customer to save money by repurposing the MiR 250 and adapt it to be useful for much heavier payloads.

Schedule a Call with an Automation Expert

We have experts in MiR technologies waiting to hear from you and consult with you on a solution that will meet your organizations’ unique needs.

Contact us or give us a phone call.

About MiR

MiR AMRs specialize in internal transportation and material handling. Our team uses the best equipment from MiR to equip our customers with the most advanced solutions on the market.